A Complete Guide to Custom Built in Cabinets

We all have areas in our home that are hard to finish with stock furniture and cabinets. Aside from kitchens and bathroom cabinets, many other areas benefit from a little attention.

The living room would look beautiful with bookcases built to surround the fireplace. Adding a custom locker unit breathes new life into a cluttered mudroom or garage. The basement is a blank slate waiting for magic.

Custom cabinets are a wonderful way to finish your space. Small spaces benefit when you have cabinets built just the right size to keep from overwhelming the area. Open floor plans with high ceilings often need large cabinets with crown molding to be a focal point that grounds the space.

Get Started on Your Home Remodel

The first step is gathering some inspiration. What are you trying to improve? A space to gather with plenty of counter space and a wine fridge that keeps your drinks at the ready. A home office that you can share without having to move stacks of paper every time you want to use the printer.

Browse on Pinterest, read home design blogs and start sketching out your vision. Don't worry about figuring out the details, just focus on the desired results. Writing your thoughts on paper helps you organize.

Focus on The Space

Next, it's time to get some dimensions. Measure your space. Be as detailed as possible. Take before pictures of your space many angles.

Pay attention to the natural way you come and go through the space. Do you always use the patio doors when guests come to visit? Keep that walkway spacious as you design the perfect island for your kitchen.

How will you use the space? Is this the main living area that ends up being home to video games and the place you bring guests? Create an entertainment center that includes plenty of storage and hides all the devices when not in use.

Meet with a Designer

Now you are ready to communicate the dream to someone who can help you achieve it. Make sure you work with a designer who understands exactly what you are looking to create.

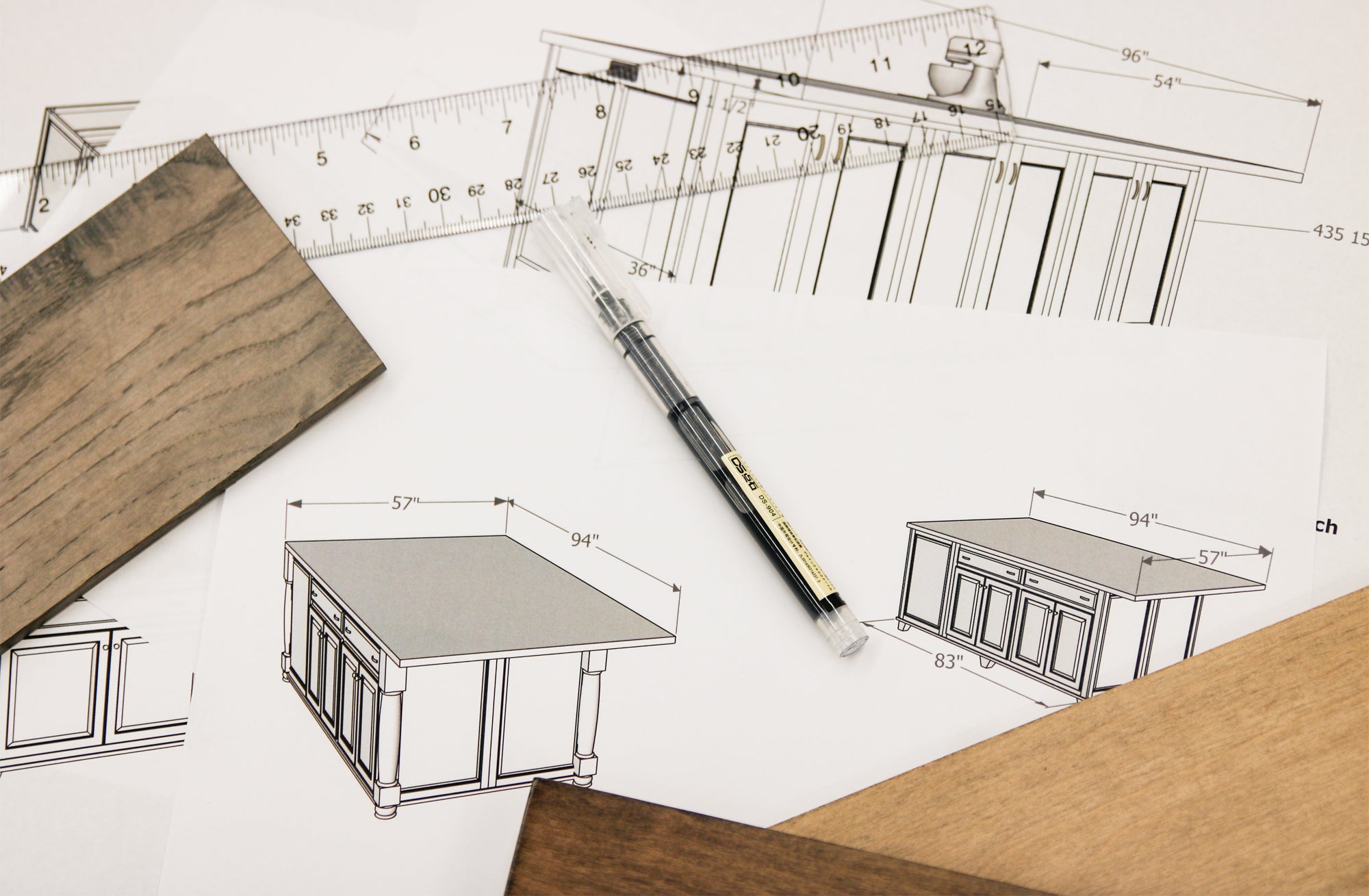

How can you be sure that the everyone involved shares your vision of the finished product? A picture is worth a thousand words. We use your measurements, pictures of the space, and your inspiration photos to create a 3D blueprint for your review. 3D drawings help our sales, craftsmen, and installation teams work together towards the same goal.

As part of creating a free quote for you, our designers will draft this drawing, complete with all dimensions. Walk through and visualize from all angles to make sure the functionality is as expected.

We can also create a complementary photo realistic rendering of the wood texture and colors selected in the space. Texture and lighting make the space come alive and calm the anxiety of making the wrong color choice.

See at a glance if you like the texture of Hickory wood on the entertainment center next to your wood floors. Maybe the fabric of the sofa is busier than you thought, just looking at the small fabric swatch. This is especially helpful in visualizing a large project.

Benefit from Product & Construction Knowledge

Every home project is different. Make sure you work with someone who understands the process involved in creating your vision.

How will you make the entertainment center fit around the existing fireplace? Is there enough space in your laundry room to add a cleaning closet? What height should the TV be in your room? How far away from the pantry doors should the custom wine rack go?

Ask questions about anything you do not understand.

Solid Wood Construction Details

Hardwood construction means understanding and working with the characteristics of the wood. We glue solid wood boards together to create panels and sides of the cabinets. Solid wood expands and contracts to adjust to the temperature and humidity fluctuations in your home. A solid wood panel can expand and contract by up to 1/4" across the width of the panel.

Each built in cabinet is unique in size and style. Our craftsmen carefully analyze the project to increase strength and stability.

Do you know that we use Grade A cabinet plywood in hidden dividers, cabinet bottoms, and back panels? The reason for this is to prevent cracks as the wood expands. We decide where to place plywood by looking for areas where the wood is surrounded on three sides, preventing it from moving.

Using plywood for these hidden cabinet sides lets the exposed, wooden face frame move without breaking or coming apart at the joints. All doors, drawers, drawer boxes, raised panels in the sides, and face frames are solid wood. We will never use particle board!

Dovetailed Drawers

When you invest in custom cabinetry, quality drawers are a must. Our Amish craftsmen dovetail all drawers to create the most durable drawer box possible. Add undermount, soft closing slides, especially great for high traffic areas like bathroom and kitchen cabinets.

What is the finish on Amish cabinets?

We finish our custom cabinets with a catalyzed conversion varnish. Simply put, the finish includes a hardening substance, known as a catalyst. We look for the hardest finish available that works with solid wood. This finish has enough elasticity to accommodate wood expansion and contraction without cracking or peeling.

Catalyzed conversion varnish is not for the at home DIY. You must mix the finish with the catalyst just prior to application and spray it on in thin coats. In contrast, thicker, polyurethane finishes are easier for woodworkers to apply at home. We must also control the finish environment at our manufacturing facility to avoid dust particles in the air.

While the catalyzed conversion varnish is the most durable option available, it is not indestructible. This wonderful option guarantees that your glass won't leave a water ring if it sweats. Heat resistant to 220 degrees Fahrenheit, you have no worries about white steam spots from your dinner plate or coffee cup.

Prevent scratches in the wood and finish by avoiding dishes with rough, stoneware type bottoms. And NEVER set cardboard boxes on the tabletop! After setting in trucks and on gritty sidewalks, boxes are prone to leave scratches in your wood tops.

At Dutch Craft Furniture, our team has years of experience in furniture sales, design, carpentry, and cabinet installation. We are happy to talk though every angle of the process! For more information on custom built in cabinets for your home, contact us today.